Recommended Products

- YXEJ Series High efficiency AC Squirrel cage brake motors

- * Frame sizes: 80 to 315 * Rated output: 0.18 to 200kW * Voltage: 380V * Frequency: 50Hz * Efficiency levels: IE2 * Enclosure: IC411 – TEFC * Degree of protection: IP55 (motor) & IP23 (brake) * Braking mode: Power failure brake * Rectification code: Half wave rectification

- YC Series Capacitor Start & Run Induction Motors

- * Frame sizes: 71 to 132 * Rated output: 0.12 to 3.7kW * Voltage: 220V,110V/220V, 110V, 240V * Frequency: 50Hz or 60Hz * Duty cycle: S1 * Insulation class: B / F * Number of poles: 2,4,6

- YLKK series medium size Vertical Type three-phase asynchronous motors (H355-630)

- * Frame sizes: 355-630 * Rated output: 185-2240kW * Insulation class: F * Enclosure: IC611 * Degree of protection: IP44/IP54 /IP55 * Rotor: Squirrel cage * Mounting: Vertical * Voltage: 6kV, 10kV * Efficiency level: IE1 & IE2 & IE3

- YLVF Series low-voltage high-power inverter three-phase asynchronous motor

- * Frame sizes: 400 to 450 * Rated output: 185 to 800kW * Insulation class: F * Voltage: 380V * Frequency range for 2P: (3) 5-60Hz (frame size 400-450) * Frequency range for 4, 6, 8, 10P: (3) 5-100Hz

- YVF2 Series Frequency Variable Speed Regulation Motors

- * Frame sizes: 80 to 355

* Rated output: 0.18 to 375kW

* Insulation class: F

* Voltage: 380V

* Efficiency levels: IE1

* Frequency range for 2P:

(3) 5-100Hz (frame size 80-250)

(3) 5-70Hz (frame size 280)

(3) 5-60Hz (frame size 315-355)

* Frequency range for 4, 6, 8, 10P: (3) 5-100Hz- YX3 Series IE2 high efficiency Three phase induction motors

- * Frame sizes: 80 to 355

* Rated output: 0.18 to 375kW

* Voltage: 380V

* Frequency: 50Hz or 60Hz

* Number of poles: 2, 4, 6, 8,10,12

* Efficiency levels: IE2

* Duty Cycle: S1

* Enclosure: IC411 - TEFC

* Insulation class: F

* Degree of protection: IP56 / IP65- Y2 Series Medium size Three phase Induction Motors

- * Frame sizes: 355-560 * Rated output: 185-1600kW * Insulation class: F * Degree of protection: IP54 * Enclosure: IC411 * Rotor: Squirrel cage * Voltage: 6Kv, 10Kv * Mounting: Horizontal

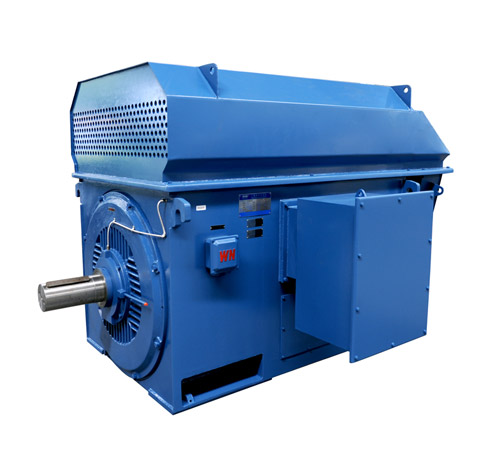

- YKK Series High Voltage Three Phase Induction Motors

- * Frame sizes: 355-1000 * Rated output: 185-8000kW * Insulation class: F * Degree of protection: IP54 /IP55 * Enclosure: IC611 * Mounting: Horizontal * Rotor: Squirrel cage * Bearing: Rolling bearing or sleeve bearing * Voltage: 6kV, 10kV * Efficiency: IE1 & IE2 & IE3

Top articles

Latest articles

- We have received Provincial Honors

- ISO Certification Re-evaluation

- Anhui Province industrial boutiques

- China Top 500 Machinery

- National May Day Labor Medal

- Chinese New Year

- Top 100 Comprehensive Manufacturing Enterprises of Private Enterprises in Anhui Province in 2023

- IE4 efficiency Explosion-proof motor has successfully passed the national supervision and random inspection

- Welcome new people to join Wannan Motor

- Wannan Motor successfully participated in EASA Fair

Your browsing history

Inspection method before motor starting

1. New or long-term stopped using motor should be inspected winding and insulation resistance to earth before motor operation. The voltage of motor below 500V often uses 500V insulation resistance meter; The voltage below 500V-1000V often uses 1000V insulation resistance meter; The motor voltage above 1000V often uses 2500V insulation resistance meter. The working voltage of insulation resistance mustn’t less than 1MΩ per KV and should be measured under motor cooling status.

2. Checked if the surface of motor has crack or not, fastening screws and spare parts are all in readiness, and if motor fixed situation is good.

3. Checked if the motor drive mechanism is reliable.

4. According to the data indicated on the nameplate, such as voltage, power, frequency, coupling, speed if is matached with the power supply and load.

5. Checked if the motor ventilatation and bearing lubrication is going well.

6. Pull the motor axis, checked if the rotor could rotation freely and has any nosies when it is rotated.

7. Checked the brush assembling condition and if the bursh-lifting device is flexible and the position of brush-lifting hand shank is right.

8. Checked if the motor earthing device is reliable.